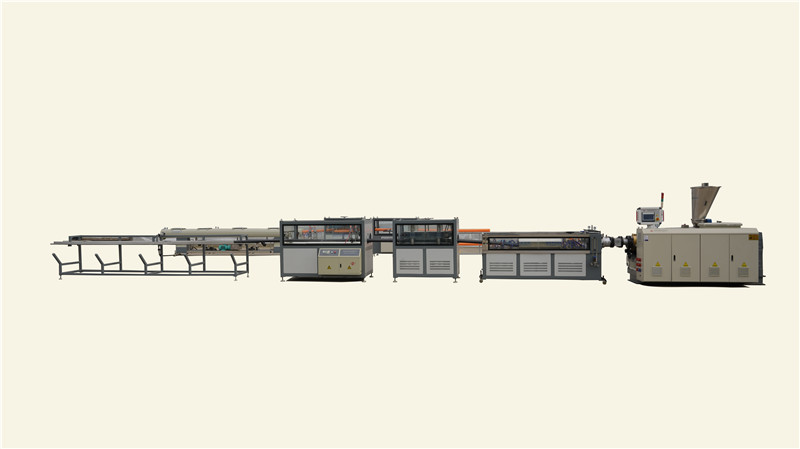

Jalur produksi pipa PVC

Rincian Parameter Téknis Tiap Mesin Luhur

1. screw loader feeder

| 1 | Diaméter pipa beban screw | mm | Φ110 |

|  | ||

| 2 | Panjang pipa screw | mm | 4200 |

2. Conical kembar screw Extruder SJSZ80/156

3. Kapang pikeun pipa PVC dua sét

4, Calibration vakum jeung cooling tank

5. tank cooling semprot cai

6. Opat pedrails haul kaluar mesin

7. Otomatis mesin motong planet

| Barang | Katerangan | Unit | Katerangan |

| ﹡Kadali PLC, motong cacah méteran otomatis, motong planét ﹡ Pneumatic clamping sarta ngaleupaskeun, Pneumatic motong balik ﹡Saw agul adopts carbide agul ﹡Kalayan alat ngumpulkeun lebu | |||

| 1 | Jenis motong | mm | motong otomatis |

| 2 | Motong diaméterna rentang cocok | mm | 75-315MM |

| 6 | Bahan Cutting Saw | baja alloy | |

| 7 | Modeu Clamping | Pneumatik | |

| 8 | Unsur Sistim Éléktronik | mm | Schneider |

| 9 | Klep tina sistem Pneumatic | Ti AIR TAC | |

| 10 | Layar toél PLC | OMRON, JEPANG | |

9. Stacker pikeun pipa rengse

Stacker

| Barang | Katerangan | |

| ||

| 1 | Mode ngadengdekkeun | Pneumatically ngajalankeun otomatis |

| 2 | Modeu kontrol | Otomatis ku sensor |

| 3 | Panjangna | 4000mm |

| 10SHRL 500/1000 mixer pemanasan / cooling speed tinggihiji set | |||

Mesin screw loader (ngirim bahan ka mixer panas) | |||

|

Mixer pemanasan

| kakuatan motor | kw | 75 |

| Panutup boiler | hiji set dijieunna tina alloy | ||

| Awak boiler | hiji set dijieunna tina stainless steel | ||

| Waktu nyampur | Min | 8-15 | |

| Lodikula &dewan pituduh | hiji set | ||

| Tangki hawa | hiji set | ||

| Suhu gawé | ≤150 ℃ | ||

| Sistim gerak hawa | hiji set | ||

| INVERTER | 75KW | ||

| MEREK INVERT | DIDAMEL DI CINA | ||

| Max kaluar nempatkeun | Kg/h | 720-920 kg/jam | |

| |||

| Adun cooling | Total kakuatan motor | kw | 11 |

| Awak boiler | hiji set dijieunna tina stainless steel | ||

| Lodicules cai ngurilingan cooling | hiji set dijieunna tina stainless steel | ||

| Ngajalankeun tekanan Cai | Mpa | ≥0.1 | |

| Alat-alat listrik ngatur set | hiji set | ||

| Platform ngadalikeun | hiji unit dilas ku baja | ||

| Volume mixer tiis | 1000L | ||

| Modél réduksi | WPO175 1:20 | ||

| Max kaluar nempatkeun | Kg/h | 720-920 kg/jam | |

| |||

11. PVC pipe mesin belOtomatis pinuh

| Parameter teknis: |

| l Modél: SGK-315 |

| l Aplikasi ranger (mm): 75-315mm |

| l Jangkungna sumbu (mm): 1000-190 |

| l Gancang ngangkut motor (KW): 1.1 |

| l Angkat kakuatan motor (KW): 1.1 |

| PLC XINJIE OR CHINA BRAND |

| Téks brand kawentar china |

| méteran kontrol hawa brand kawentar china |

| l Photoelectric switch brand kawentar china |

| l Air-break switch Delixi |

| l Kontaktor Schneider Perancis |

| l komponén pneumatic: bran kawentar china |

| l Air silinder: china jeung Italia joint venture |

12. 600 PVC pulvertizerwww.cuishimachine.com www.cuishiextruder.com

1, Nurutkeun kana karya panas sarimbag: sanggeus ngalakonan pagawean per jam kana 860 kcal panas, mesin ieu knalpot éksternal, volume hawa badag, ku impor jeung ékspor tina bédana hawa angin atas nama lolobana panas, a bagian leutik panas direngsekeun ku cooling cai.Syarat: Suhu inlet cai cooling henteu langkung ti 25, suhu cai outlet henteu langkung ti 50, sareng aliran cai cooling leres-leres ningkat dina usum panas pikeun ngirangan suhu.

13. SWP630 PVC pipah Crusher

Sistem kabinét listrik: Asesoris utama nyaéta Siemens atanapi Schneider

- Jumlah knives pindah: 6 lembar

- Jumlah péso tetep: 4 potongan

---Sistem pangiriman hawa:

+ Motor: 3Kw - Brand Beureum Bandéra

+ Volume hopper hawa stainless steel: 100 méter kubik (liter)

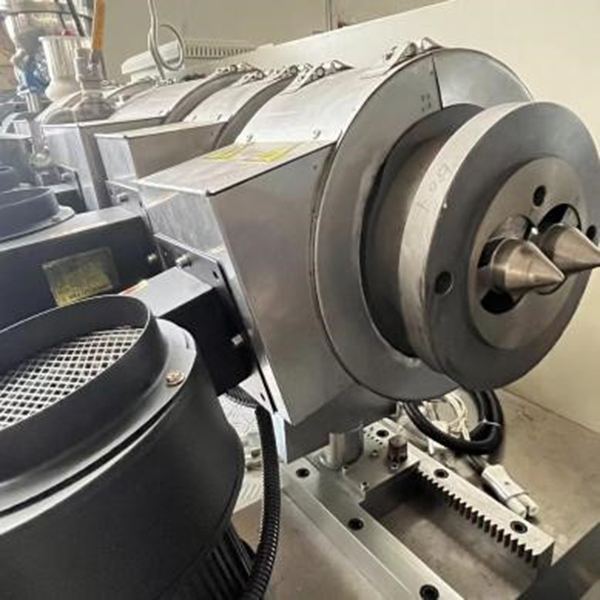

14.PVC pipe Thread Mesin motong

200-315mm Otomatis pipe internal tur éksternal mesin thread

| 1 | ngetik | CS-315 |

| 2 | Diaméter pipa | ¢200mm/¢250mm/¢315 mm |

| 3 | Panjang pipah | 3m,6m |

| 4 | jangkungna puseur | 1000mm |

| 5 | Paké tegangan | 380V, 50HZ,3 fase |

| 6 | tekanan hawa dikomprés

| 0,6 Mpa |

| 7 | Total kakuatan | 8KW |

| 8 | Motor utama | 3KW |

| 9 | Motor maju | 0,75KW |

| 10 | kakuatan kipas lebu | 3KW |

| 11 | Ngangkat kakuatan motor | 0,37KW |

| 12 | adjustment jangkungna | adjustment listrik ---- ku tombol |

| 13 | Warna mesin | Kalayan kabutuhan customer |

| 14 | Ukuran mesin | 8370*2250*2300 |

| 15 | beurat mesin | 2800KG |

| 16 | tipe thread | Thread éksternal T ngawangun jeung thread internal T ngawangun |

| 17 | Bahan sabeulah | W18Cr4V |

15 MESIN GROOVING pipa