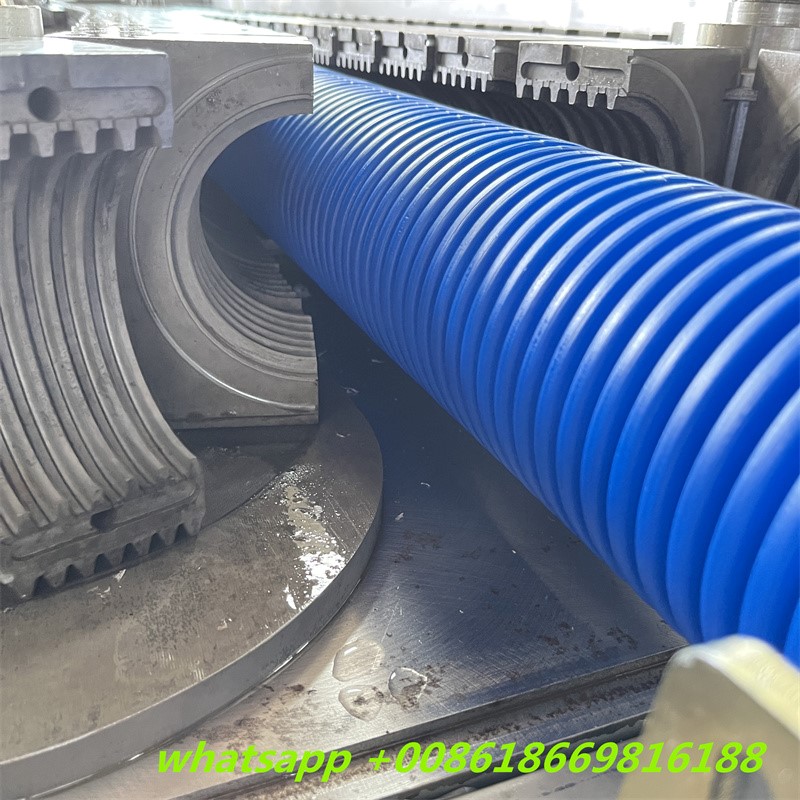

Jalur produksi pipa PVC (50-200mm)

| Jalur produksi pipa PVC1 set Double-Screw Extruder - SJSZ65/132 Kalayan motor INOVINCE SERVO, kualitas luhur 1 set otomatis screw loader 1 set kapang pikeun 50.63.75.90.110MM 1 set kapang pikeun 125.140.160.200MM 1 set tina vakum calibration cooling tank 1 set tina tilu hileud haul off mesin 1 set mesin motong Planét 1 sét Stacker |

| SHR300/600panas jeung tiis mixer |

| Mesin beling pipa PVC otomatis sareng kapang jinis U |

| SWP500 crusher kalawan fungsi cucipikeun crusher pipa PVC tina 20-250mm 22kw motor Pindah péso 7 PCS, ngalereskeun péso 2 PCS, output 400-500kg / h |

| Mesin giling PVC |

| ﹡Screw, desain tong sareng manufaktur nyerep téknologi canggih Éropa ﹡Bahan sekrup sareng tong: 38CrMoAlA, diolah nitriding ﹡adopsi komponén listrik kawentar aslina kalawan kualitas jalan ajeg tinggi.Contona: RKC atanapi Omron suhu controller, AC speed regulator, low-tegangan breaker adopts Schneider atanapi Siemens ﹡Gearbox ngadopsi torsi tinggi, noise low, teuas gear huntu beungeut gear box ﹡Sistem pelindung diri: ayeuna tina overload motor panyalindungan eureun otomatis pamindahan screw panyalindungan eureun otomatis Minyak lubrication kalaparan alat alarem otomatis Screw jeung tong | |||

| 1 | Diaméterna screw | mm | ¢65/132 |

| 2 | Panjang screw | mm | 1430 |

| 3 | Bahan Screw sareng Laras | / | 38CrMoAlA Nitrogen Treatment |

| 4 | Kedalaman kasus nitrasi | mm | 0,4-0,7 mm |

| 5 | Teu karasa nitrat | HV | 》940HV |

| 6 | Kakasaran beungeut | Ra | 0.4eun |

| 7 | Teu karasa alloy ganda | HRC | 55-62 |

| 8 | Jero alloy ganda | mm | 》2 |

| 9 | Daya pemanasan | KW | 24 |

| 10 | Laras Pemanasan | / | Casting Aluminium manaskeun |

| 11 | Barel Cooling | / | Low noise blower cooling |

| Kasus transmisi | |||

| 1 | standar lumaku | / | JB / T9050.1-1999 |

| 2 | Bahan tina gear jeung aci | / | Ngadopsi alloy kakuatan tinggi, carburizing na quenching, grinding |

| 3 | Precision gear jeung karasa | / | kelas 6, HRC 54-62 |

| 4 | Sealing minyak | Kabéh sealing ngadopsi produk alus | |

| 5 | Screw Safeguard | / | Alarm kapindahan screw otomatis |

| Dosing alat dahar | |||

| 1 | Tipe | / | Screw dosing feeder |

| 2 | Dahar kakuatan motor | KW | 1.5 |

| 3 | Regulator laju dahar | / | INOVINCE Brand inverter |

| Sistem motor sareng listrik | |||

| 1 | Daya Motor | KW | 37 (INVOVINCE SERVO MOTOR) |

| 2 | Mode nyaluyukeun speed | / | Holip atawa konvérsi Frékuénsi kawentar sejenna nyaluyukeun |

| 3 | Max Kaluaran Kamampuh | Kg/h | 50-300 kg |

| 4 | Sistim haseup vakum | / | ku pompa vakum |

| 5 | Suhu Controller | / | Siemens / DELTA / OMRON |

| 6 | Kontaktor AC | / | Siemens / DELTA / OMRON |

| 7 | Voltaseu | / | Numutkeun sarat |

| 8 | jangkungna sumbu Extruder | mm | 1000 |

2. Paeh sirah pikeun pipa PVC tina 50-200mm

| Barang | Katerangan | Katerangan |

|

| ||

| 2 | Bahan awak kapang | Baja 45 # (baja kapang unggul) |

| 3 | Bahan bagian jero dina kapang | 40Cr (baja kapang unggul) |

| 4 | Bahan tina calibrator | Kuningan |

| 5 | Ketebalan dinding pipa (Laju tekanan) | Sakumaha diperlukeun |

3. POMPA VACCUM CALIBRATION tank tank cooling

Calibration vakum sarta tank cooling

| Barang | Katerangan | ZK-200 | |

| fungsi: calibrate diaméterna luar jeung tiis | |||

| 1 | Panjangna | 6000mm | |

| 2 | Bahan tina tanki | beusi sténless | |

| 3 | Tipe Cooling | Cai Semprot-tuang cooling | |

| 4 | kakuatan Pompa Cai | 4KW × 2 lembar | |

| 5 | kakuatan Pompa vakum | 5,5KW × 1 PCS | |

| 6 | adjustment posisi kénca jeung katuhu | Nyaluyukeun manual | |

| 7 | gerakan bulak-balik | Dipindahkeun ku motor (tipe roda cycloidal-pin) | |

4. Tilu hileud ngangkut unit

Tilu cakar Pedrials Hauling kaluar Mesin

| Barang | Katerangan | QY-200 |

| fungsi:Tarik pipa PVC maju sacara stabil, laju disingkronkeun sareng laju extruder. | ||

| 1 | Jumlah Pedrail | 3 |

| 2 | Lebar pedrail | 55 mm |

| 3 | Pedrail sadia Panjang | 1900 mm |

| 4 | Max.Angkatan Angkut | 20KN |

| 5 | Pedrail Clamping sarta ngaleupaskeun Mode | Pneumatic Drive |

| 6 | Ngangkut Daya Motor | 2.2KW |

| 7 | Laju Angkut | 0,5~5m/min |

| 8 | Disetir jeung transmisi | drive sentral;transmisi cardan |

| 9 | Mode Nyaluyukeun Speed | Konversi frékuénsi variabel |

| 10 | Jangkungna Axis | 1000mm |

5. Planét Mesin motong

| Barang | Katerangan | CH-200 | |

| fungsi:Méter cacah motong otomatis pipa PVC dina panjangna tetep. | |||

| 1 | Modeu motong | Otomatis méteran cacah motong | |

| 2 | Motong kakuatan motor | 2,2kw | |

| 3 | Revolusi motor Power | 1,5KW | |

| 4 | Eupan motong sabeulah | Dahar hidrolik | |

| 5 | Koléksi lebu | Ku blower hawa kalawan 1.5kw | |

| 6 | Clamping sarta ngaleupaskeun Mode | Pneumatik | |

| 7 | Balikna longitudinal pindah | Ku silinder hawa pneumatically | |

| 8 | Bahan saw | kualitas alus alloy baja | |

| 9 | Cara kontrol | kontrol Siemens PLC | |

| 10 | Merk inverter | merek Schneider | |

6.Stacker

| 1 | Modél | SFL-200 |

| Aplikasi:Pipa PVC tihang. | ||

| 2 | Bahan papan pituduh | Beusi sténless |

| 3 | Panjangna | 6M |

| 4 | Métode Discharging | Pneumatic ngurangan |

| 5 | Puseur Jangkungna | 1000mm |

| 6 | Jangkungna Nyaluyukeun | ± 50 mm |

| 7 | Beurat | 480kg |